Polyethylene Sinks

Three types of installations for Polyethylene (PE) sinks

Scientific Corrosion Resistant Even-Flow Sinks

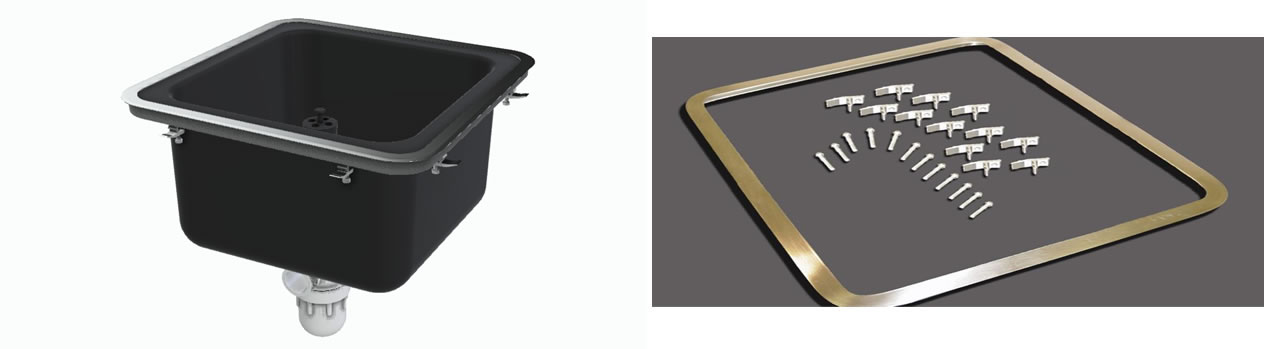

Undermount With Steel Support Rim

1 - Undermount with steel support rim. This is the most common application. The countertop cutout for this style installation is based on the inside bowl dimensions with a 1/8" to 1/4" overhang of the counter into the bowl. A steel rim is provided to secure through the bottom of the sink flange to the bottom of the countertop, be it Epoxy or Lab Grade Phenolic Resin. (Rendering Right).

The undermount hole cutout will be based on the actual bowl size of the specified sink. Undercounter mount steel rims are supplied to assist in securing the sink to the bottom of the countertop. Cut hole to the interior bowl size of the Poly sink then use the custom undercounter rim that seats below the flange of the sink and secure by screws. Predrill holes into the underside of the counter.

View 3D Rendering of the Undermount Sink - Click Here

Stainless Steel Flush

2 - Stainless Steel Flush mount rim. All PE sinks are trimmed to fit into a flush mount rim. The countertop cutout for a flush mount installation is based on the OD of the support rims, as the rim fits down into the countertop, with the rim flange on top of the counter and includes "Lugs", tightened to hold the sink in place.

The PE sink is matched with appropriately sized flush mounted rim and hardware. The hole size is cut to outside dimensions of the J-channel of the flush mount rim. The sink can then be secured into the interior of the J-channel to secure into place and installed hardware to secure rim to countertop.

For installers who are cutting countertops in the field for Flush Mount applications, we recommend having the rim and sink on hand before cutting the hole in the counter, to assure proper cutout dimensions. We will provide you with a set of cutouts for flush mount rim installations for any of our sinks. These cutouts will be based on the flush mount rim, so it will fit into the counter top, and the sink will then fit into the rim.

View 3D Rendering of the Stainless Steel Sink - Click Here

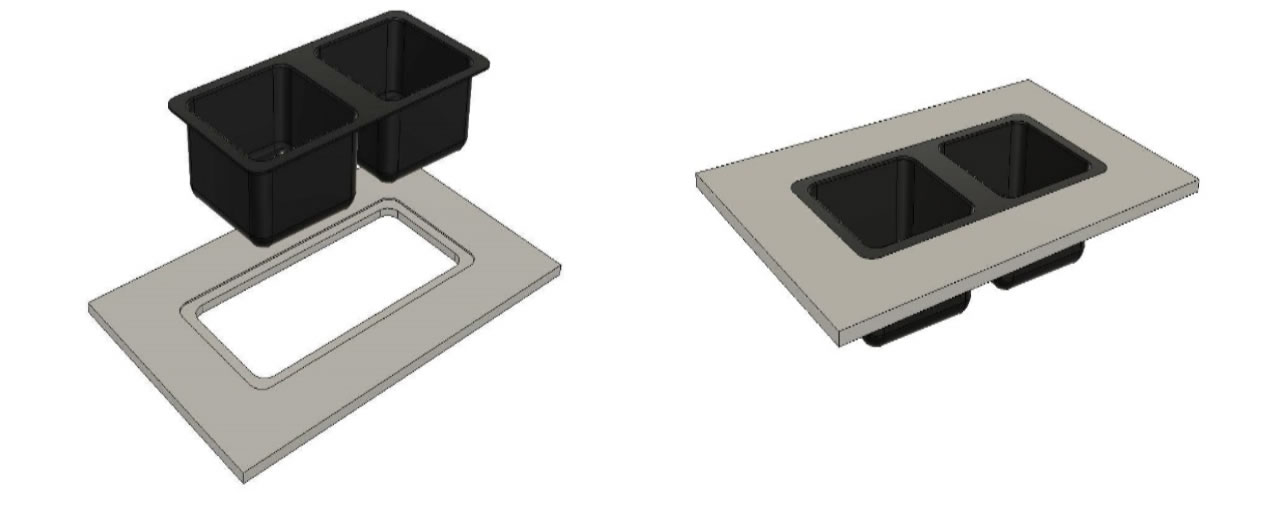

Drop In Installation

3 - Drop in installation. This uses a rabbeted or recessed cutout into the Epoxy Resin or Phenolic Resin countertop. The sink flange rests on the rabbeted ledge and the top of the sink rim is flush or recessed below the counter top. There is no mechanical attachment of the sink rim to the counter per se, but see below** - Use Smooth-on Epoxy Resin adhesive for mounting in this style application. Scuff up the bottom of the PE flange with a 60 grit sand paper and wipe clean, as the PE sinks are Smooth and Non- porous and this will facilitate greater bonding of the adhesive to the underside of the sink rim. Make sure enough pressure is exerted along the entire perimeter of the PE rim to assure proper counter adhesion.

With a Drop-in sink, the hole cutout will be based on the OD dimensions of the sink from exterior flange to flange with 1.5" radius on all corners, with a slight overcut of approx. 1/8" all sides, for ease of final install.

A 3/8" depth rabbet/recess will need to be fabricated into the counter to allow the sink to be nested into the countertop cutout, as the thickness of the actual sink lip is +/- 0.25"" thick. All dimensions with rotationally molded sinks are +/- .125" on all sides. The Thickness at the rim is 1/4" (6 mm) with the flange/rim width of 1.25" (31.75 mm) The Corner radius for Exposed PE sinks is 1.5" (38 mm) on all exposed corners

FIELD FABRICATION: For installers or fabricators who are cutting countertops in the field for a rabetted / recessed type application, we also recommend having the sink on hand before cutting the hole in the counter, to assure proper cutout dimensions. Determine or template the OD of the sink, tape the outline and overcut the outside edge of the cutout by 1/8" on the four sides with a router bit. This will result in a recessed vertical cutout of approx. 3/8" depth and a horizontal ledge of approx. 1/2" wide.

**Undermount support is not typically required with smaller & light weight polyethylene sinks, however we do recommend supporting larger sinks with uni-strut or on-site floor supports as required by application.

While poly (PE) sinks are dimensionally similar to epoxy sinks, the structural strength of polyethylene (Polyolefin) is different. If you consider a poly sink with a 10" overflow stand pipe can accumulate 6-10 gallons of water in the sink; and at 8#/gallon water weight this is a constant load of 50# to 80#+ on a polymer lip.

If the end user is just flowing water through the sink it may never be an issue. But if they are loading it up with glassware, containers and standing water, we recommend some type of uni-strut or floor support to compensate for the weight and pulling at the rim. The uni-strut support is only there to support any load that may be placed into the sink bowl.

We are NOT responsible for any distortion or deflection that may take place after install of the polyethylene sink that does not utilize under sink support.