DURCON® Epoxy Tops

FABRICATED TO YOUR EXACT SPECIFICATION

Fabricated Lab Grade Epoxy Resin Tops

FABRICATED WORK SURFACES, factory cut in accordance with approved shop drawings, are typically known in the industry as "Universal" countertops and are equivalent in detail to "Classic Tops" when fabricated with a 1/8 (3mm) bevel or 1/4" (6mm) radius and chamfer bottom edge. Other fabrication detail includes sanded edges, along with sink cutouts (lipped or undercounter mount), applied or factory molded marine edge, drip groove, set-on, field applied splash, faucet, eye wash and gas tap holes, notches, electrical box cutouts, column cutouts, etc., all offered at an additional modification charge. Durcon Epoxy Resin lab tops are offered and fabricated from in-stock slabs by Total lab Solutions.

Thickness tolerance for all surfaces, fabricated or slabs, from each corner of top, shall not deviate more than plus / minus 1/32" (1.5mm overall) from normal, per Laboratory Work Surfaces & Accessory design specifications, section 12345. Size tolerance in epoxy countertops shall be plus / minus 1/8" (3.175mm). Applied Epoxy joints between sheets should not exceed 1/8" (3mm).

According to Specification, epoxy countertops are to be secured to base cabinets with the factory supplied Smooth-On 2-part epoxy resin adhesive cement, applied at each corner and along perimeter edges at not more than 48 inches (1219mm) on center. When necessary to penetrate countertops with fasteners, countersink heads approximately 1/8" (3mm) and plug hole flush with material equal to countertop in chemical resistance, hardness and appearance.

Our Production Process

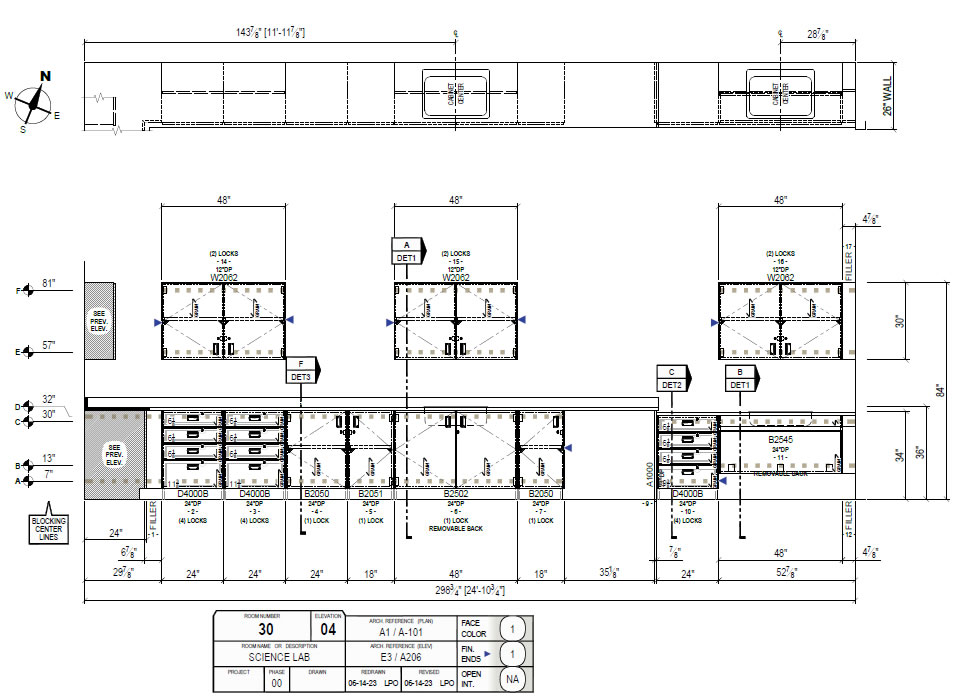

Submit Drawings

Send In final architectural or company drawings. We provide a full takeoff of all relevant items.

Quote Provided

After a complete review of all epoxy/phenolic tops, sinks, pegboards... we provide a detailed quote for fabrication and delivery.

Fabricate and Ship

Our team fabricates to your exact specs, safely packs and ships your items for local installation.

Get A Quote: Send In Approved Architectural Drawings

Architectural Specifications for work surfaces shall be either 3/4" (19mm) or industry standard 1" (25mm) thick molded composite thermosetting epoxy. A maximum of 1.25" (32mm) can be molded as a one-piece monolithic sheet. The Durcon epoxy surface finish shall have a non-glare satin or matte finish. All exposed edges shall be eased to the specified radius, bevel or chamfer as required in architectural drawings.. All front overhang edges of 1" (25mm) on the work surface shall be factory machined to have a 1/8" x 1/8" drip groove on the front underside at a distance of approximately 1/2" (13mm) from the outside edge.

All holes for lipped drop-in or undermount epoxy resin / polyethylene / stainless steel sinks and fittings shall be factory cut with a CNC Router. Splash back and side splash shall be the same material, thickness, color and finished as the work surface. Splash backs shall be 3/4 or 1" thick, supplied cut to size, and shipped loose for field installation.

All joints between unfinished sections of tops shall be butt jointed and bonded on site with an approved bonding agent such as Smooth-On Epoxy Adhesive joint compound to ensure a smooth water tight, leak proof joint. Laboratory countertops shall be maintained regularly with common non-abrasive household cleaners. After cleaning, a light application of Scott's Liquid Gold or similar mineral oil will help protect the surface. Spills shall be cleaned immediately to prevent chemical or hard water attack to the surface of the laptops or sink materials. Dry ice or liquid nitrogen should not come in contact with epoxy resin countertops or sink materials for any prolonged period of time.

Sample Customer Architectural Drawing